via LumberJocks.com RSS Feed - All Posts http://lumberjocks.com/brucethecontrarian/blog/34942

Wonderful Things

“Lord Carnarvon said to me `Can you see anything’. I replied to him, ‘Yes, it is wonderful.”

• Exchange between Lord Carnarvon and Howard Carter at the opening of Tutankhamun’s tomb.

The Vision

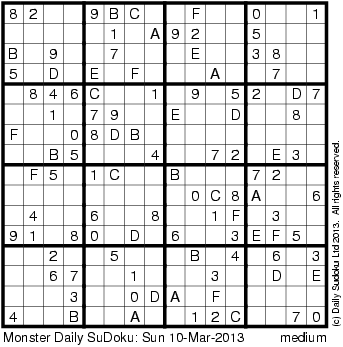

Figure 1 – Wonderful Things

Just like Carter’s, this is a story of discovery, and, unlike Carter’s, making wonderful things with some bits of wood. Lately my workshop has become overfilled with junk (or treasured heirlooms) belonging to She (Who Must Be Obeyed) and bits of wood that should, surely, be consigned to the burn pile. It is a bit like one of those puzzle squares with 15 tiles and 16 spaces where only one tile can be moved at a time and to get to the furthest piece an intricate ballet must be performed. I spend far too much time moving things out of the way or looking for things buried under other things – aaarrgghhh! In short, it is an awful workspace but, like Carter, I look in there and see wonderful things.

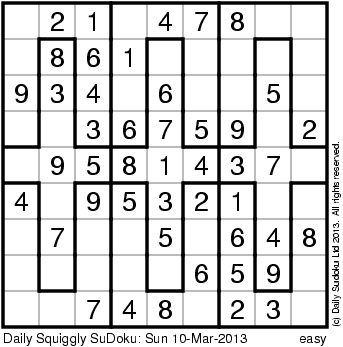

Figure 2 – Not So Much (yet)

But the first wonderful thing I need to see is a workshop that is squared away and fit for use as a workshop and not as a full-scale model of a down market undiscovered tomb of a really untidy Pharaoh. So, where to start?

Organisation!

A tidy workplace is an efficient workplace and the best way to tidy a shop is to throw out all the detritus (treasured heirlooms and garden stuff that rightly belong in the Potting Shed of She) that just don’t belong. However, as She has Views on treasured heirlooms, and as the Potting Shed of She is full of other She stuff, the next best thing in organising is storage. Storage needs to be part of an overall organisation as, otherwise, individual bits of clutter end up as big boxes of clutter and you still can’t work because stuff is still in the way. Now all I need is a Plan.

The Plan

The workshop is not like those American workshops seen on TV (lookin’ at you Norm, Roy, Tommy), it is far from prairie sized (10’ by 16’) or even double garage sized but is still big enough or should be. The problem is that most of it is lost to poor, inappropriate or non-existent storage and the current use of the “first available flat surface” (FAFS) storage method. Sometimes the FAFS is the top of previously FAFS stored items, it is then termed a “heap”. The goal here is to make flat surfaces available for doing stuff.

Maybe not so much a plan as actually doing stuff; stuff to be done:

Phase 1:

• Under bench drawers to get rid of the current freeform storage shelf (stuff just piled there). My initial thoughts are for planes and chisels and measuring tools.

• Under table saw drawers as the space is currently not used (an empty store bought metal closed in stand) to be used for screws, nails and other hardware. The added weight should make the machine more stable in use.

• Finish off drawers in jointer/planer stand.

Phase 2:

• Transformation of treasured heirlooms (small wardrobe and [broken] chest of drawers) into more storage while retaining outward heirloom appearance.

• Rationalisation and organisation of woodpile (to include a cart?).

• Clamp storage – let’s face it we all need this.

• Power tool storage drawers doubling as carry cases where I do not have one.

• Cupboards to put carry cases in.

• Saw till.

Phase 3:

• Dust collection. Maybe this should come earlier but until the workshop is squared away there is no way to fit it.

• Master the mystery of the broom and dust pan.

• Find all of those things which were put down just a minute ago over and have never been seen since.

Phase 4:

• Maintenance (tools and machines).

• Maintenance (workshop).

In parallel the production of wonderful things needs to continue as She wills it. Also by doing all of this stuff it will also reduce the woodpile, which alone takes up too much space and is desperate need of rationalisation. Well, that’s the plan. Now, the only reason to have a plan is so that you know when you are carrying it out or, more usually, not. This plan is not serial; the phases can be done out of sequence and the individual elements can be performed as the need or opportunity arises. Remember, flexibility is the key to indecision.

Crafty Puzzles