I was so excited to try making a picture frame for an old mirror I etched a long time ago… until I got this disaster of a clamp.

Pros:

- Nylon band is an easy to see day-glow orange.

- Solid easy to grip handle

- Quick release tabs on either side makes it easy to size the band accordingly

- Really long band – like 15’ long. A bit large for a 12×12 picture frame, but I’m sure for an odd shaped item it would come in handy.

Cons:

- Has a little notch (for lack of a better term) on the inside of each corner clamp piece that allows mitered joints to slide into causing cockeyed joints.

- Corner clamps feel like they are made out of plastic that would snap under any real clamping situations.

- Somehow marred the wood

I won’t try to make this a seething hate filled review, but I do want to forewarn that this little clamp might be better suited to something like round chair legs, or something like that. When it comes down to it I really liked the feel and heft the main clamping handle had to it, but after I got it out of the package I noticed a couple odd things. For one the left (as seen in the picture) quick release popped up at a funny angle as if it was bent. I thought maybe it just locked into place at first, but upon further inspection it seems like the little hinge spring that holds it on was forced down to align and be put in the package. Then again this may be a return/resale because there is a tiny hole in the left side of the main clamp attached to the handle. Kind of looks like someone previously had it out and stuck it with an icepick or something.

So beyond all the weird little stuff that I noticed when I pulled it out I figured I’d give it a go anyway, and cut a few mockup test pieces for a picture frame I’ve had in mind. When I first clamped with it I noticed that the one side with the oddly angled quick release was slowly letting the band back out after tightening it. It took me a minute or so to really notice it, but after I went to pick it up after tossing the waste part of the cuts it just came undone like I hadn’t tightened it at all except by pulling the strap down by hand and not cranking any pressure to it. So after that happened I watched the band and could see the webbed texture slowly going past the exit point toward the frame. This in mind I diddled with the flippy release thing and couldn’t figure out what the deal was so I did what any other red-blooded testosterone producin’ dude would do; tightened it reaaaaally hard. I laugh now, but wow was I angry when the clamping handle flipped up over the workpiece and shot one of the mitered pieces right off the table it was on, and into a very personal um, place.

Fun part came when I finally tried a dozen or so times at rebanding around the outside and clamping, and then my wife came and took a look and gave it an honest shot too. Same thing happened minus the shot to the um, place I mentioned before.

I like the thought of this product. I just don’t think it was well executed because another issue I had was tightening the band made it stretch/thin-out (if that makes sense) and come out from under the little plastic clips that hold the clamping corners on so when it does pop it harkens back to a commercial I remember seeing some time ago in my younger days for a game called perfection. Unless you got all the pieces lined up into the proper slots faster than the timer it would explode and little oddly shaped plastic pieces would go flying everywhere.

Perhaps I’m just still to much of a newbie at all this, but really… how hard is it to line up a bunch of c-shaped plastic clips and crank a handle? Either way I’m going to take it back tomorrow, and use the money I spent on it to buy two Multifunction Corner Clamps from Harbor Freight. I’ve had nothing but good luck with those in the past when I used some from a buddy of mine. Which brings me to my final point. If this wasn’t priced as high as it was I’d just chalk it up to a learning experience, but when I can return one clamp that doesn’t work for me & get two that do, why not? Not saying that this clamp may not work for you. Just didn’t work so well for me.

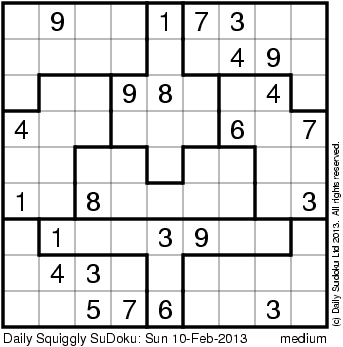

Crafty Puzzles