via LumberJocks.com RSS Feed - All Posts http://lumberjocks.com/jjw5858/blog/34358

I was having a rather cold and uninteresting time trying to draw up plans for my recent Country carving throne project so I set my feet to the woods for some pine that may allow me to create a piece to use in my shop. I knew just off the edge of the woods where I could fetch a pretty good chunk for a rustic bench to use for various tasks from sawing, hewing, etc. I needed to connect with some outdoor timber work, get the blood flowing (it was a cold day!) and have some challenges to try and meet my satisfactions with.

Our weather was off and on presenting temperatures of 30-35 degrees with short sessions of light snow. The air was clear as I walked in the shop to collect my two man/one man keystone saw. About an eighth mile down my dirt road off towards the woods I walked into a small path where I approached the bull pine timber I sought after. This sadly was another hurricane sandy victim and not too long off I took the midsection away for a bowl horse or clave I also want to make for the shop.

Here is the piece in progress …......ahhhhh the mighty pine!

I guess although I love getting that ebay win or cheap auction find I try to use all of these tools so I can learn how they are of best use. Collecting is fine and appreciated but they were made to use in some form. I think somewhere in the winds those former souls of craftsmen guide you along with the appreciation that the new owner continues to learn the ropes of the old dogs. So if it’s an old hand tool in great shape I give it care and use it a little.

As the sawing began I was sure to randomly hit my saw with some wd-40 making the kerf a much smoother ride as the heavy sap was soon to stick the job too tight to continue. I paced myself since this style of work is not something I usually do although the wd-40 made the exercise ease through finality in about 20 minutes.

I have sawn through, not as bad as I originally had planned.

I enjoyed the work breaking for a few seconds here and there just looking around taking the pine aroma in and thanking the good lord for feeling so free in the rythm of the outdoors. Once I cut through such a piece I feel this connection with it, like you had to gain it’s respect with your sweat and hard work. I love that the most in this sort of task, the climb is in fact just as rewarding as the last coat of linseed oil as you stand back and snap the finished picture of your project. This old bull pine is one mean lady, heavy, unforgiving grain, gold and rich with knots the size of large stones that will buck your hatchet edge almost just as hard.

Standing one end up and somehow rigging it in my grandfathers old red wheel barrow my senses were in high regard knowing full focus and skill were nesseceary for backing this timber out to the dirt road. The diameter was a healthy 9.5 inches as the weight was more than enough. I gained my rythm in pulling the barrow along and up the slight incline back towards the shop to unload my catch.

On to the barrow with care and steady moves!

Back to the shop and time to shave the bark off, a sharp drawknife suits you for a handy way of dealing with this.

The work here is a wonderful chore, especially if the scent of pine is a favorite to breathe in…..lucky me..lol.

This portion of the task is done, now onto the relieving of the top by splitting…..or so I think…lol.

I would love to tell you that this pine with some wedges split down like a champion, but this piece needed to school me. I wedged, I hammered, I wedged some more and noticed the small split beginning and then the lesson was to be had…lol. No way will you split through these knots, it is just not going to happen. My German nature is sometimes a bit hard headed indeed, and I realized I forgot to read the map of the grain, I was lost in tunnel vision of the creation, well off the path of the message the wood was conveying to me with every heaving smash of hammer to thy wedge….lol.

So, we have to find a way, and nothing would work better than to simply make relief cuts fairly close together and chisel the top pieces out! I forgot the shot of the final pieces dismissal but the relief cuts pictured did a nice job, although those knots still were a battle to knock out cleanly.

This was hard work, I sure needed it too. This work tames a bad attitude quick and tempers your focus to the warmest measures. I felt extremely alive in the 30 degree shop, sawing down relieving another portion, muscles burning, sawdust shaking to the ground. It was a totally invigorating process, challenging the roughest cut work, beauty was on hold in place of gritting out the exercise to produce the raw form of this rugged wood. I felt those chopped knots guiding my will to see the whole thing through, and was sure that years after I will always remember this cold night in the shop executing the cuts to my desired vision.

Of course such extensive physical wood work feels better as you plow through in cold weather, although I humbly admit the layout and lines of cabinetry yearns for warmer thinking conditions as I held off working on my country carving throne…lol.

A pine puzzle if you will. I forgot my ways excusing grain pattern fundamentals and would paid the price…lol.

The oldest tricks for the oldest of trades, when in doubt relief cuts to lose the wood. Make no mistake those knots held tough even still.

Took some 2×3 lumber and rounded some tenons for possible legs!

With spokeshave in hand sitting at the shave horse is a wonderful way to get great exercise as well as a much needed skill building session of using a spokeshave. I recalled watching the great chairmaker Brian Boggs work a chair piece down at the horse and was awed by his sense of absolute skill in the shaving of it.

Here is a rough sketch giving the basic setup of what this would be handy for.

This is a shop project, something I tend too when I can. I am hoping to get this and my bowl horse (or clave) up for the spring. The bowl horse/clave is another log split affair used for making wooden bowls or even jigged properly with wedges is available for wooden clog making!

Well I suppose I should clog onward myself, I hope you enjoyed seeing some of this madness.

”Take time and enjoy those things thought as little, as you may someday see they are far greater in your empty days and yearn for their forgotten gifts” JJW

Thank you for your time,

Shave on!

Joe

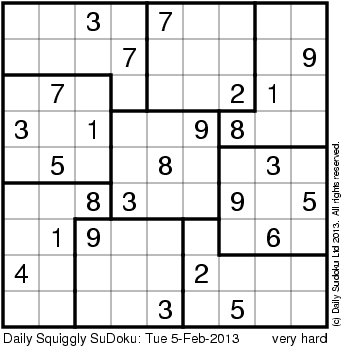

Crafty Puzzles